STEEC » Micro-cutting and precision laser machining

Micro-cutting and precision laser machining

Precision laser ablation and micro-cutting are among the activities of STEEC in Brindas, near Lyon.

a range of laser skills

We provide you with a range of laser skills using a machine specialized in performing micro-cutting on tubular parts as well as ablation using a femtosecond laser source.

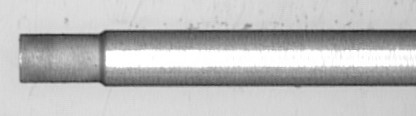

Using this innovative and high-performance machine, the production of your very high precision parts on tubular blanks whose diameter can vary from 10mm to 0.2mm is possible with the laser cutting process.

We can machine your parts using micro-laser cutting, whether they are made of Nitinol, ferrous or non-ferrous alloys, as well as polymer materials.

With a machine with a USP (ultra – short -pulsed) source, also called a femtosecond source, your specific needs such as ablation operations with a precision of the order of a few microns can be carried out.

high precision complex geometries

The use of this machine also allows the production of complex geometries with very high precision.

Branches that can go down to around a few µm thick with diameters less than a millimeter.

In the figure on the right taken in x240 the hexagonal-shaped stent has 20 µm branches on a 0.7 mm diameter stainless steel tube.

Contact us

Your complex parts can also be produced with us using laser micro-machining operations on flat parts or even drilling, micro-milling, turning or wire EDM operations in Brindas.

Tubular parts made by micro-cutting or laser ablation are used in sectors with extreme requirements such as aerospace or medical.