STEEC » Areas of intervention

The manufacture of micro-components and its areas of intervention

Areas of intervention of STEEC, specialized in the manufacture of micro-components

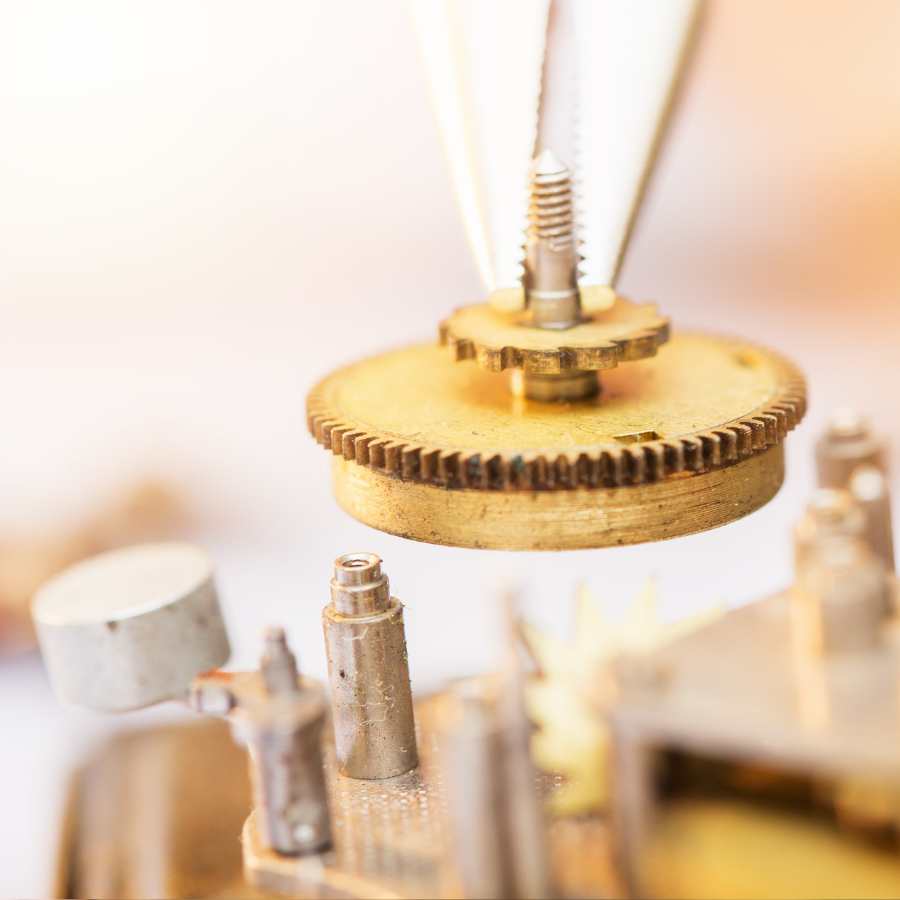

Precision micromechanics

We are able to provide you with solutions for your micro-component manufacturing needs thanks to our solid know-how. Our various sectors of activity allow us to provide you with technical solutions for your projects.

Whether you come from the medical, aerospace, aeronautics, nuclear, research, watchmaking, automotive and many other sectors, we are your partner.

Most fields have one thing in common: complex needs and extreme demands!

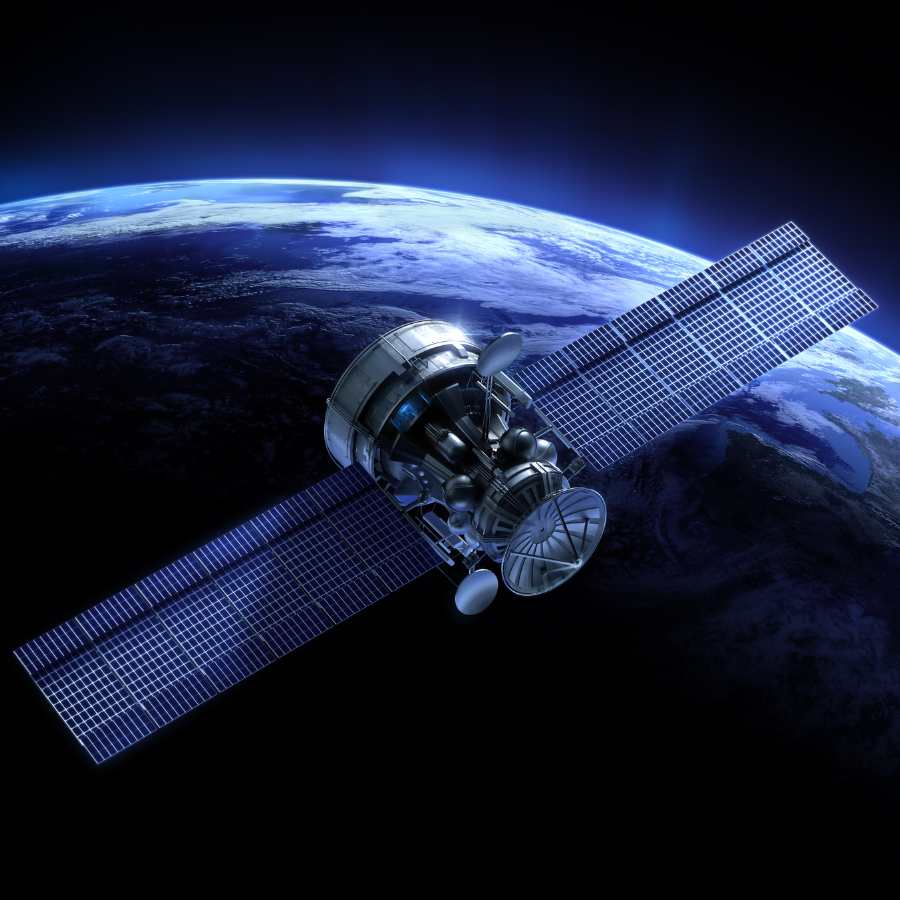

We are proud to be a leading supplier to major aerospace industry clients in France and abroad, such as Thales Alenia Space, Airbus Defence and Space, etc.

We produce very high precision parts as a supplier to many companies in the medical sector.

Nuclear is a sector that requires extreme precision as well as great rigor. This of course also concerns machining.

STEEC, a company eligible and approved for the Research Tax Credit, is a partner of many prestigious research centers such as the CNRS or the CEA.

Since its creation in 1979, STEEC has offered, thanks to wire EDM cutting in particular, the machining of parts for molds and dies for all types of industries.

Thanks to its high-precision laser micro-cutting technology, STEEC is able to offer high-quality services that can be applied in fine watchmaking.