Sinking and micro-driving by electroerosion

Discover the parts made by STEEC in Brindas for several sectors of activity.

This modern machining technology offers many advantages over more conventional processes.

STEEC offers its customers its expertise in electro-erosion die-sinking.

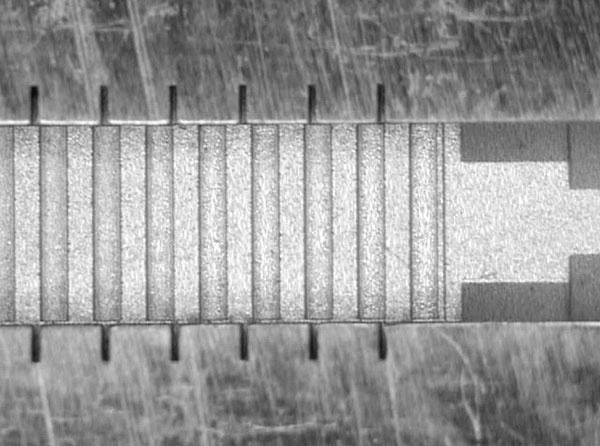

The principle of this machining process is the same as for wire EDM, with the difference that the cutting tool is no longer a wire but an electrode shaped according to the desired precision machining. The part and the tool (electrode) are therefore not in contact, it is an electric arc formed between the electrode and the part which machines the latter. This is also called sparking.

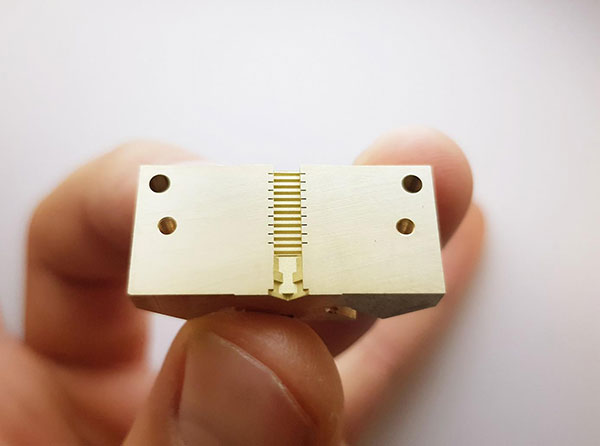

Micro-drilling work on a machining center

The part must absolutely be conductive to be able to be machined using this technique. This is the sine qua non condition for using this process.

This absence of contact between the tool and the part allows sinking EDM to machine very hard materials such as titanium for example.

This process also allows for great flexibility in the variety of machined shapes since STEEC manufactures most of its own machining electrodes.

STEEC can therefore meet a very wide range of customer demands. Thanks to its ultra-high-precision micro-sinking process using electrical discharge machining (EDM), STEEC is able to offer its customers machining services for blind and complex shapes with tight tolerances. The smallest sinking diameter achievable by EDM is on the order of thirty microns, plus or minus a few microns.

This technology can find applications in all sectors of industry thanks to the very good surface finish and the resulting high precision. Micro-drilled parts by electroerosion can be found in the medical, aerospace, nuclear and research fields.

Feel free to contact us for your needs in micromechanics and micro-drilling.

Contact us

For more information regarding micro-milling, do not hesitate to contact us.

We also carry out the micro-drilling and the milling.