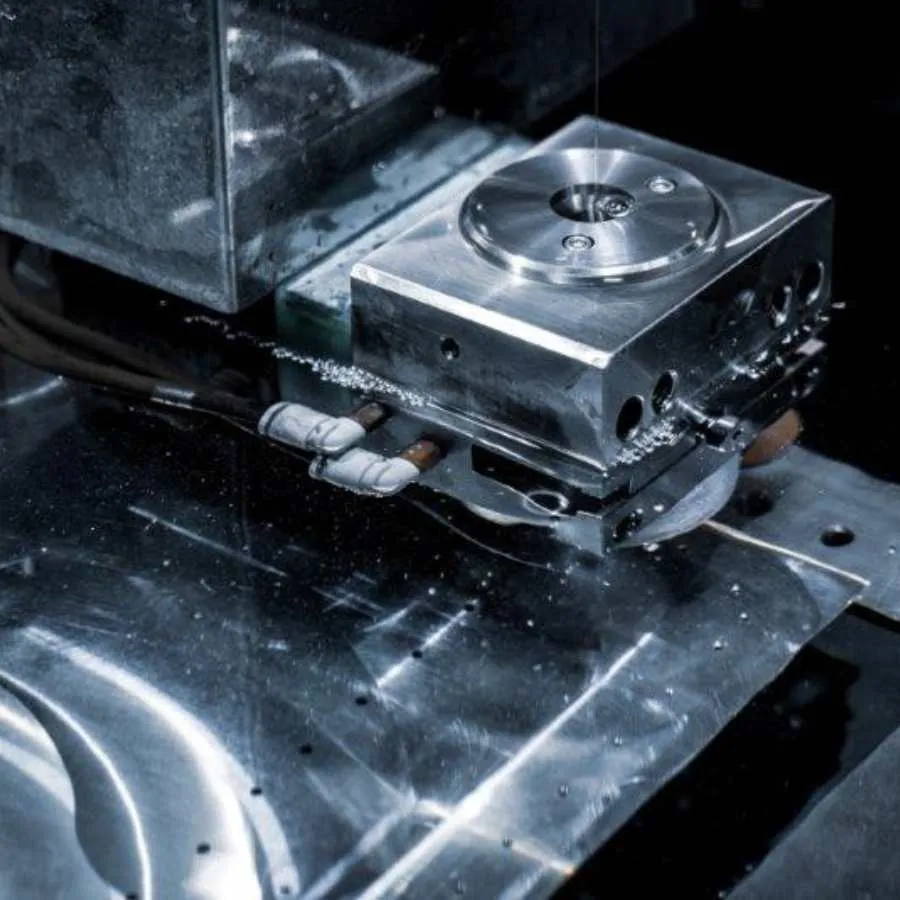

Precision machining

STEEC's expertise at the service of cutting-edge industries

A specialist in precision machining for several decades, STEEC designs and manufactures high-value-added technical parts for the most demanding industrial sectors. Our expertise is based on mastery of micromachining processes and laser micro-cuttingallowing for extreme levels of precision, down to a few microns.

Located near Lyon, STEEC accompanies its clients from the feasibility study to the production of individual parts, prototypes or small series, with a high level of reliability and repeatability.

Ultra-high precision machining adapted to critical applications

Precision machining is for areas where zero tolerance does not exist.

Our solutions are designed to meet the technical, regulatory and functional constraints of cutting-edge industries:

Medical – Optics – Aeronautics – Space – Nuclear – Defense

Each project benefits from a tailored approach, integrating dimensional requirements, material properties and end-use conditions.

Discover our service as well micro-cutting of flat parts.

What is precision machining?

Precision machining refers to all mechanical manufacturing processes that produce parts with extremely small dimensions, very tight tolerances, and a high-quality finish. It is used in applications where even the slightest dimensional variation can impact the operation, safety, or performance of the final product.

Unlike conventional machining, precision machining requires specific technical resources, a controlled production environment, and highly skilled human expertise.

Why is precision machining essential?

In many industrial sectors, components must meet strict requirements regarding:

- dimensional accuracy (down to a few microns)

- repeatability and geometric stability

- surface quality

- long-term reliability

This machining process makes it possible to guarantee these criteria, particularly for miniaturized, complex parts or parts subjected to high mechanical, thermal or functional constraints.

Precision micromachining and micro laser cutting

STEEC has a full range of laser skills, notably thanks to a machine dedicated to micro-laser cutting of tubular parts and ablation operations using femtosecond laser source (USP – ultra short pulsed).

This cutting-edge technology enables:

- the production of very high precision parts on tubular blanks from Ø 10 mm to 0.2 mm

- machining of complex geometries, even on extremely thin thicknesses

- ablation operations with a precision on the order of a few microns, without thermal degradation

Precision machining of technical materials

Our laser machining and micro-cutting processes are suitable for a wide variety of materials, including:

- Stainless steel and technical steels

- Ferrous and non-ferrous alloys

- Nitinol

- technical polymers

This versatility allows us to meet complex specifications, including for miniaturized parts with high mechanical constraints.

Why should you trust us?

French made

Since 1979

French Fab Label

French industrial know-how

Certified company

ISO 9001 and ISO 13485 standards.

STEEC, unique expertise for 45 years

A high-precision machining project?

Do you have a need for precision machining, micro-machining or micro-laser cutting for a demanding application?

STEEC supports you with reliable, innovative solutions perfectly adapted to your industrial constraints.

Contact us to discuss your project or request a quote.